product

Our holding company proudly operates in the field of exporting high quality food. Our products include aseptic apple puree and concentrate, aseptic tomato paste, authentic Iranian tea, dates, aseptic puree of bell pepper, aseptic pumpkin puree, and aseptic grape concentrate. Focusing on the use of advanced aseptic technologies, we ensure that our products reach our dear customers worldwide with full preservation of taste and nutritional value. Our goal is to provide healthy and quality products to international markets and satisfy customers through commitment to high health and quality standards.

Commitment to quality

Aseptic tomato paste

Attributes:

High quality: Aseptic tomato paste is produced using fresh and ripe tomatoes, which preserves its natural flavor and color.

Uniform texture: The aseptic process makes the tomato paste have a uniform and homogeneous texture.

Long shelf life: Due to the aseptic packaging process, this product has a long shelf life without the need for preservatives.Advantages:

Retention of nutritional value: The aseptic process helps to preserve the vitamins and nutrients of the tomatoes.

More health: No need to add preservatives or chemical additives makes this product a healthier option for consumers.

Ease of use: Aseptic packaging allows for easy use and long-term storage.

Wide application: Aseptic tomato paste can be used in the preparation of various foods, sauces and soups.Production methods:

Selection and washing of tomatoes: Fresh and high quality tomatoes are selected and carefully washed to remove any contamination and impurities.

Chopping and cooking: Tomatoes are chopped and then cooked at a controlled temperature to reach the desired consistency.

Filtration: The cooked mixture is passed through different filters to separate the skin and seeds and obtain a uniform and smooth product.

Sterilization: Tomato paste is sterilized at high temperature and pressure to kill any harmful microorganisms.

Aseptic packaging: The sterilized paste is placed in a completely hygienic and airless environment in aseptic packaging, which allows for long-term shelf life without the need for chemical preservatives.

Storage and distribution: Aseptic packages of tomato paste are stored in controlled warehouses and ready for distribution to domestic and international markets.

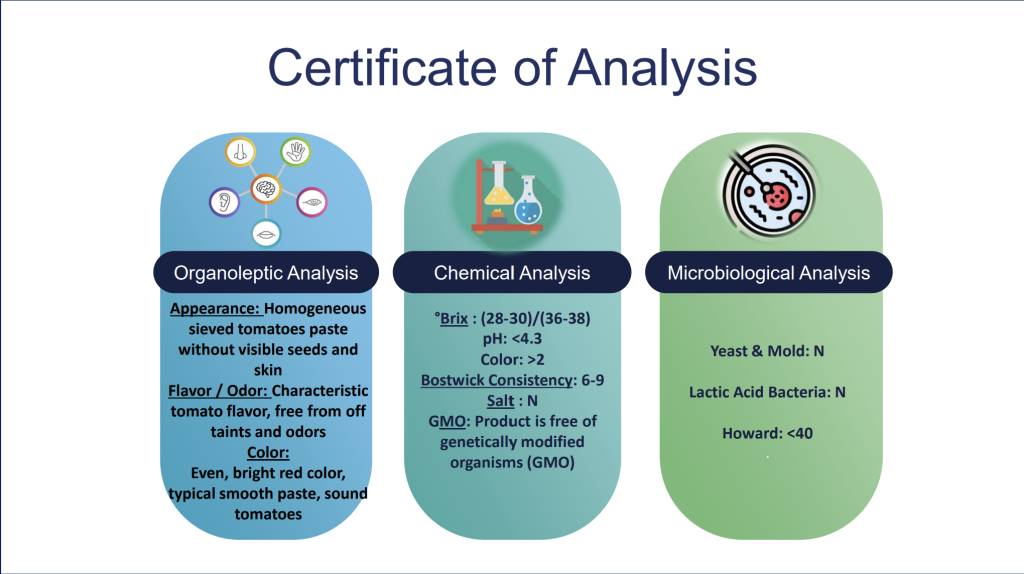

Certificate of analysis

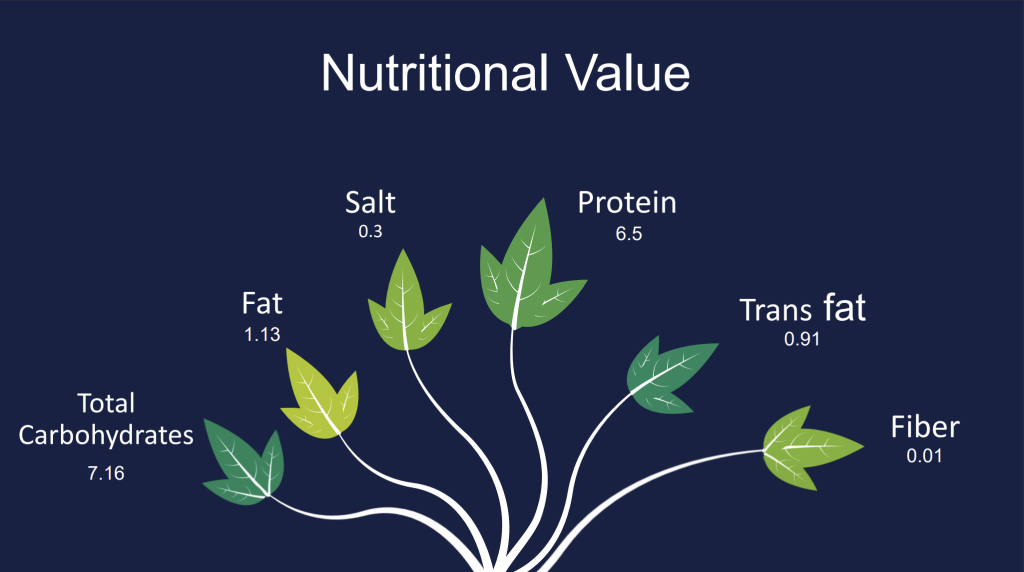

Nutritional Value

Aseptic puree and apple concentrate

Attributes:

High quality: Apple puree and concentrate are made from fresh, ripe and high quality apples, which preserves the natural taste and aroma of the fruit.

Uniform texture: The manufacturing process makes applesauce smooth and uniform in texture, while apple concentrate is thicker and stronger in flavor.

No artificial additives: These products are prepared without artificial preservatives, colors and flavors.Advantages:

Preservation of nutritional value: the production process is such that vitamins, minerals and fibers in apples are preserved.

Healthier: Without added chemicals and preservatives, apple puree and concentrate are healthier options for consumers.

Multiple use: These products can be used in the preparation of all kinds of desserts, sauces, drinks and baked goods.

Long shelf life: Apple concentrate has a longer shelf life than puree due to its high concentration and proper packaging.Production methods:

Selection and washing of apples: fresh and high quality apples are selected and carefully washed to remove any contamination and impurities.

Chopping and cooking: Apples are chopped and cooked at a controlled temperature until soft.

Pureeing: Cooked apples are turned into puree and passed through different filters to separate the skin and seeds and obtain a uniform product.

Concentrate: To prepare concentrate, apple puree is concentrated through water evaporation process to obtain a highly concentrated product.

Sterilization: Apple puree and concentrate are sterilized at high temperature and pressure to destroy any harmful microorganisms.

Aseptic packaging: Sterilized products are placed in a completely hygienic and airless environment in aseptic packaging, which allows for long-term shelf life without the need for chemical preservatives.

Storage and distribution: Aseptic packages of apple puree and concentrate are stored in controlled warehouses and ready for distribution to domestic and international markets.

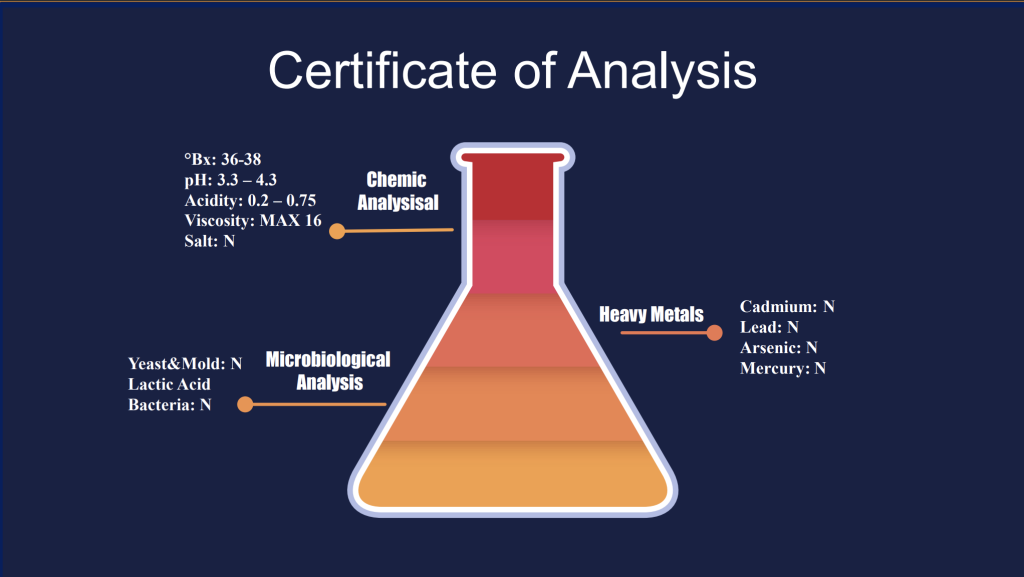

Certificate of analysis

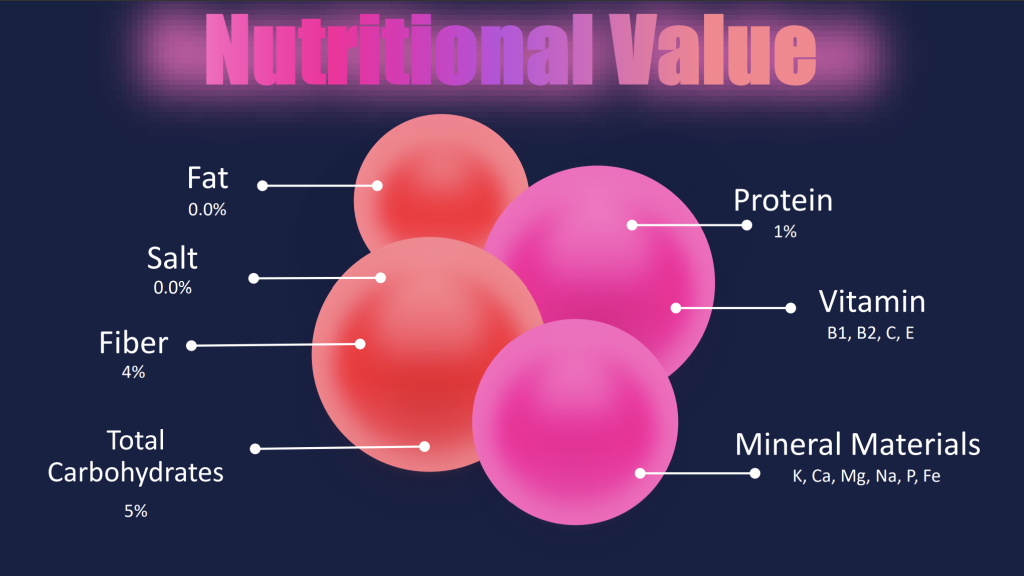

Nutritional Value

Aseptic grape concentrate

Attributes:

High quality: grape concentrate is prepared from fresh, ripe and high quality grapes, which preserves the natural taste and aroma of the fruit.

High concentration: The concentrate production process makes the final product thicker and with a stronger taste and color than grape juice.

Variety of colors and flavors: Depending on the type of grapes used, grape concentrate can have different colors and flavors such as white, red, and black.Advantages:

Preservation of nutritional value: the production process is such that vitamins, minerals and antioxidants in grapes are preserved.

Long shelf life: Due to its high concentration and proper packaging, grape concentrate has a longer shelf life than fresh grape juice.

Multiple uses: grape concentrate can be used in the preparation of all kinds of drinks, desserts, sauces, baked goods and even as a natural sweetener.

Economical transportation: Due to the smaller volume compared to grape juice, transportation and storage costs are reduced.Production methods:

Selection and washing of grapes: fresh and high quality grapes are selected and carefully washed to remove any impurities.

Extraction: washed grapes are crushed and their juice is extracted.

Filtration: The grape juice is passed through different filters to remove any solid particles and impurities.

Concentration: Filtered grape juice is concentrated through the process of evaporation under vacuum (vacuum evaporation) to remove its excess water and the final product reaches the desired concentration.

Pasteurization: The concentrated concentrate is pasteurized under controlled temperature to kill harmful microorganisms.

Aseptic packaging: The pasteurized grape concentrate is placed in a completely hygienic and airless environment in aseptic packaging, which allows for long-term shelf life without the need for chemical preservatives.

Storage and distribution: Aseptic packages of grape concentrate are stored in controlled warehouses and ready for distribution to domestic and international markets.

Aseptic pumpkin puree

Attributes:

High quality: Pumpkin puree is made from fresh, ripe and high quality pumpkins, which preserves its natural flavor and color.

Soft and uniform texture: The production process makes the pumpkin puree have a soft and uniform texture.

No artificial additives: This product is prepared without artificial preservatives, colors and flavors.Advantages:

Preservation of nutritional value: The production process is such that the vitamins and nutrients in pumpkin are preserved, including vitamin A, vitamin C, potassium and fiber.

Healthier: Without added chemicals and preservatives, pumpkin puree is a healthier option for consumers.

Multiple uses: pumpkin puree can be used in the preparation of various foods, desserts, soups, sauces and baked goods.

Ease of use: This product is easy to use and can be used directly in cooking.Production methods:

Selection and washing of pumpkins: fresh and high quality pumpkins are selected and carefully washed to remove any contamination and impurities.

Peeling and chopping: Pumpkins are peeled and then cut into smaller pieces.

Cooking: Pumpkin pieces are cooked at a controlled temperature until soft.

Pureeing: Cooked pumpkins are turned into puree and passed through different filters to obtain a uniform texture.

Sterilization: Pumpkin puree is sterilized at high temperature and pressure to destroy any harmful microorganisms.

Aseptic packaging: Sterilized puree is placed in a completely hygienic and airless environment in aseptic packaging, which allows for long-term shelf life without the need for chemical preservatives.

Storage and distribution: Aseptic packages of pumpkin puree are stored in controlled warehouses and ready for distribution to domestic and international markets.

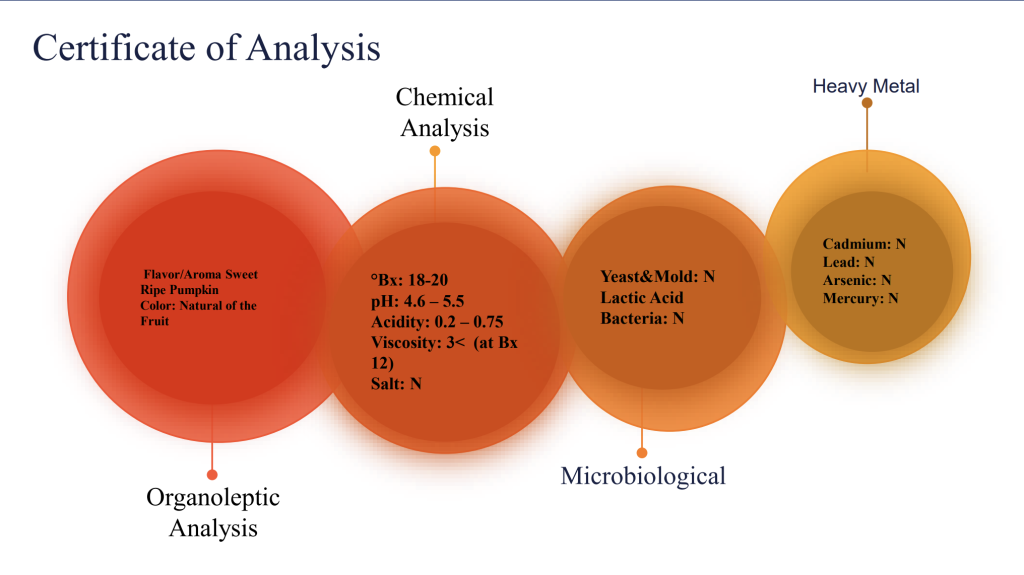

Certificate of analysis

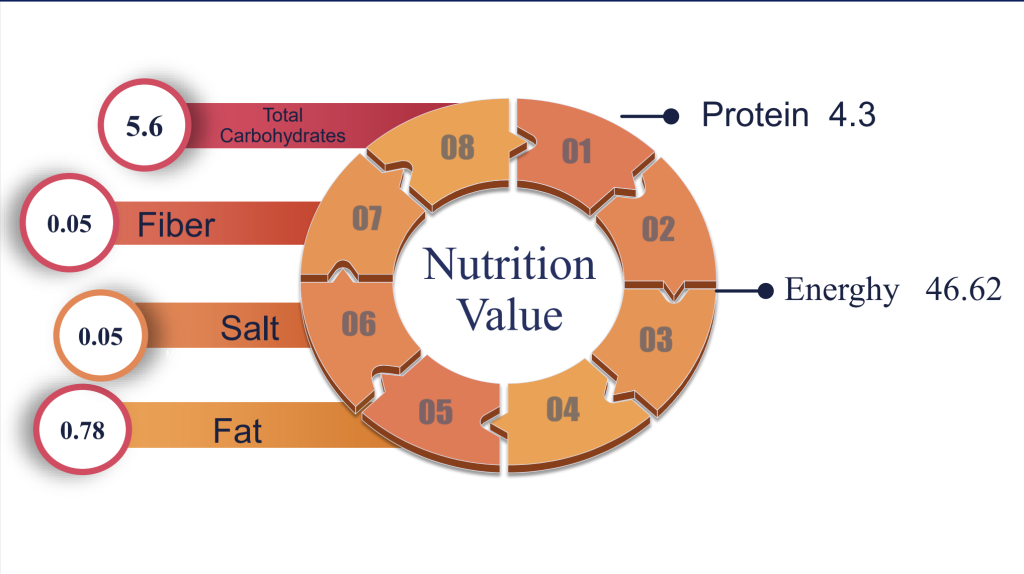

Nutritional Value

Aseptic sweet pepper puree

Attributes:

High quality: Sweet pepper paste is made from fresh, ripe and high quality peppers, which preserves its natural flavor and color.

Soft and uniform texture: The production process makes sweet pepper puree have a soft and uniform texture.

No artificial additives: This product is prepared without artificial preservatives, colors and flavors.Advantages:

Preservation of nutritional value: The production process is such that the vitamins and nutrients in bell peppers are preserved, including vitamin C, vitamin A, potassium and fiber.

Healthier: With no added chemicals or preservatives, bell pepper puree is a healthier option for consumers.

Multiple uses: sweet pepper puree can be used in preparing all kinds of foods, sauces, soups, desserts and baked goods.

Long shelf life: due to aseptic packaging, this product has a long shelf life without the need for preservatives.

Ease of use: This product is easy to use and can be used directly in cooking.Production methods:

Selection and washing of bell peppers: fresh and high quality peppers are selected and carefully washed to remove any contamination and impurities.

Chopping and cooking: The peppers are chopped and cooked at a controlled temperature until soft.

Pureeing: Cooked peppers are turned into puree and passed through different filters to separate the skin and seeds and obtain a uniform texture.

Sterilization: Sweet pepper puree is sterilized at high temperature and pressure to destroy any harmful microorganisms.

Aseptic packaging: Sterilized puree is placed in a completely hygienic and airless environment in aseptic packaging, which allows for long-term shelf life without the need for chemical preservatives.

Storage and distribution: Aseptic packages of sweet pepper puree are stored in controlled warehouses and ready for distribution to domestic and international markets.

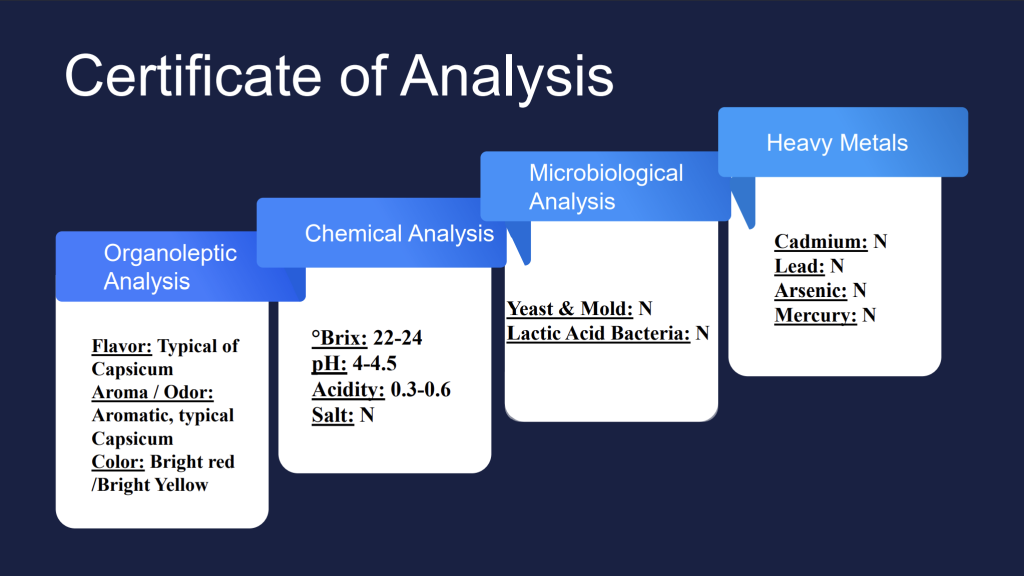

Certificate of analysis

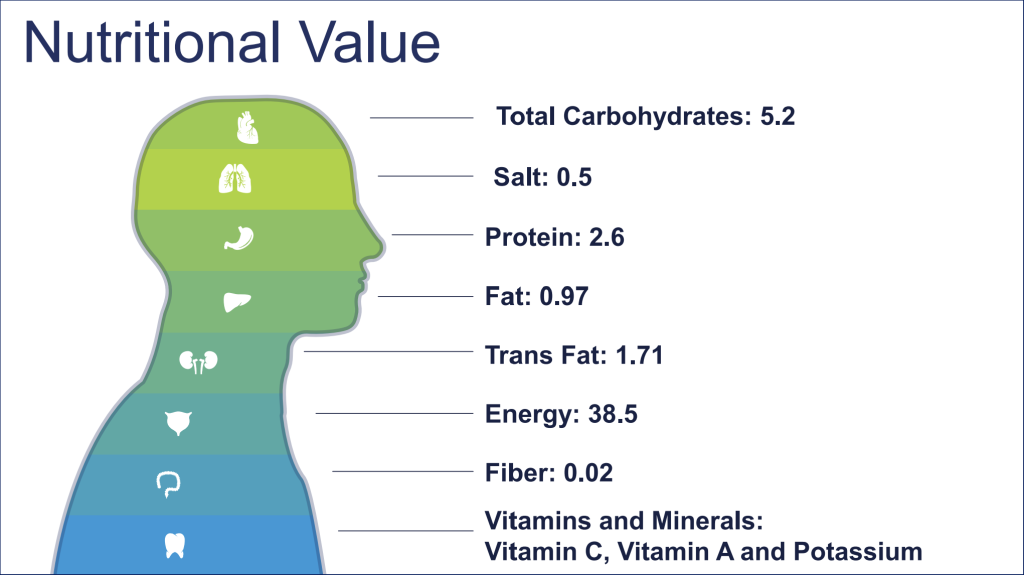

Nutritional Value

Date

Attributes:

Rich in nutrients: Dates are rich in vitamins and minerals such as vitamin B6, potassium, magnesium and fiber.

Natural sweet taste: Dates have a sweet and pleasant taste that can be used as a natural sweetener in foods and desserts.

Energetic: Dates are a rich source of energy, due to their high content of carbohydrates and natural sugars.

Variety of species: There are different types of dates that are different in terms of taste, texture and size, such as Majul dates, Payaram dates and Retb dates.Advantages:

Digestive health: The fiber in dates helps to improve the functioning of the digestive system and prevent constipation.

Heart health: Potassium and magnesium in dates help maintain heart health and lower blood pressure.

Antioxidants: Dates contain powerful antioxidants that help reduce inflammation and protect cells from oxidative damage.

Increased energy: Due to the high content of natural sugars, dates are a quick source of energy for the body.

Various uses: Dates can be used fresh, dried, or in the preparation of various food products such as date juice, jam, and cake.Production methods:

Harvesting dates: Dates are collected from palm trees during the ripening season. Harvest time may vary depending on the type of date.

Washing and cleaning: Dates are carefully washed to remove any dirt and impurities.

Drying: Some types of dates are dried after washing. This process can be done naturally (in the sun) or industrially (using drying machines).

Grading: Dates are graded based on size, color and quality so that the final product is uniform and of high quality.

Packaging: Dates are placed in hygienic and appropriate packaging to protect them from contamination and damage. Packaging can include small packages for home consumption or larger packages for industrial use.

Sterilization: Some date products, such as date juice or processed dates, are sterilized to make them last longer.

Storage and distribution: Date packages are stored in controlled warehouses and ready for distribution to domestic and international markets.

Iranian tea

Attributes:

Unique taste: Iranian tea is known for its special taste and aroma, which is caused by the special weather conditions of the northern regions of Iran, especially Gilan and Mazandaran.

Natural color: Iranian tea is prepared without artificial colors and additives and has a natural and transparent color.

Variety: There are different types of Iranian tea, including black tea, green tea, and white tea, each of which has its own unique properties and characteristics.

Advantages:

Heart health: regular consumption of Iranian tea can help reduce the risk of heart diseases due to the presence of antioxidants.

Improving digestion: Iranian tea helps to improve the functioning of the digestive system and reduce problems such as bloating and indigestion.

Anti-inflammatory: Antioxidants and anti-inflammatory compounds in Iranian tea help to reduce inflammation and strengthen the body's immune system.

Increasing concentration: drinking Iranian tea helps to increase concentration and mental alertness due to its caffeine content.

Natural and organic: many Iranian tea producers use organic cultivation methods without the use of chemical pesticides, which helps the product to be healthier.

Production methods:

Planting and harvesting: Iranian tea is planted in tea gardens located in the northern regions of Iran. Tea leaves are usually harvested in spring and summer.

Withering: After harvesting, the tea leaves are spread out in a cool, well-ventilated area to lose some of their moisture. This step helps to soften the leaves.

Rubbing and Twisting: Withered leaves are rubbed to break the cells and release the tea's aroma. This process also causes the leaves to curl.

Fermentation (for black tea): At this stage, the rubbed leaves are placed under controlled conditions to allow the fermentation process to take place and the color and flavor of the tea to develop. This step is removed in the production of green and white tea.

Drying: Fermented tea leaves are dried in dryers or exposed to hot air to minimize their moisture and make them last longer.

Grading: Dried leaves are graded based on quality, size and appearance.

Packaging: Graded tea is placed in hygienic and suitable packaging to protect it from moisture, light and pollution. Packaging can include small packages for home consumption or larger packages for industrial use.

Storage and distribution: tea packages are stored in controlled warehouses and ready for distribution to domestic and international markets.